Blogs

29 June 2021

Reading Time: 5 mins

Blogs

29 June 2021

Reading Time: 5 mins

Supply chain, operations, and IT managers are increasingly driven by the “desire to be more digital” says Amber Salley, director and analyst, Gartner. Supply chains were unquestionably disrupted by COVID-19 in 2020 and 2021 – we need only cast our minds back to shortages in toilet rolls, Easter eggs, and most recently a lack of vaccine doses in Europe.

This has driven enterprises to explore how supply chain management can be improved with new technologies and digital initiatives.

Want to learn how to use IoT to streamline operations and reduce wastage across the supply chain? Check out our whitepaper on Continuously Connected Global Supply Chains.

Organizations are increasingly leveraging the Internet of Things (IoT) to optimize supply chain processes, increase agility, and build resilience. Smart supply chains enable real-time insight and monitoring of products wherever they may be in the supply chain, wherever they are in the world.

Traditionally, supply chain management (SCM) is controlling the movement of goods and services as they travel and progress from initial manufacturing through to distribution and consumption. The process involves managing an ecosystem of relationships throughout the supply chain cycle.

By implementing IoT, supply chain management is greatly enhanced with up-to-date fresh data which offers up complete visibility to parts of the supply chain that were previously dark. Data accuracy is crucial for informing supply chain decisions and aiding reactive responses to demand and consumption in fast-paced environments.

Inventory, inventory, inventory. Understanding where inventory is, and gauging inventory levels is key for supply chain managers. In an ideal world, every product would be fitted with a discreet IoT device, which continuously transmits data on location, temperature, movements that may cause damage, human interaction, and so on, throughout the journey.

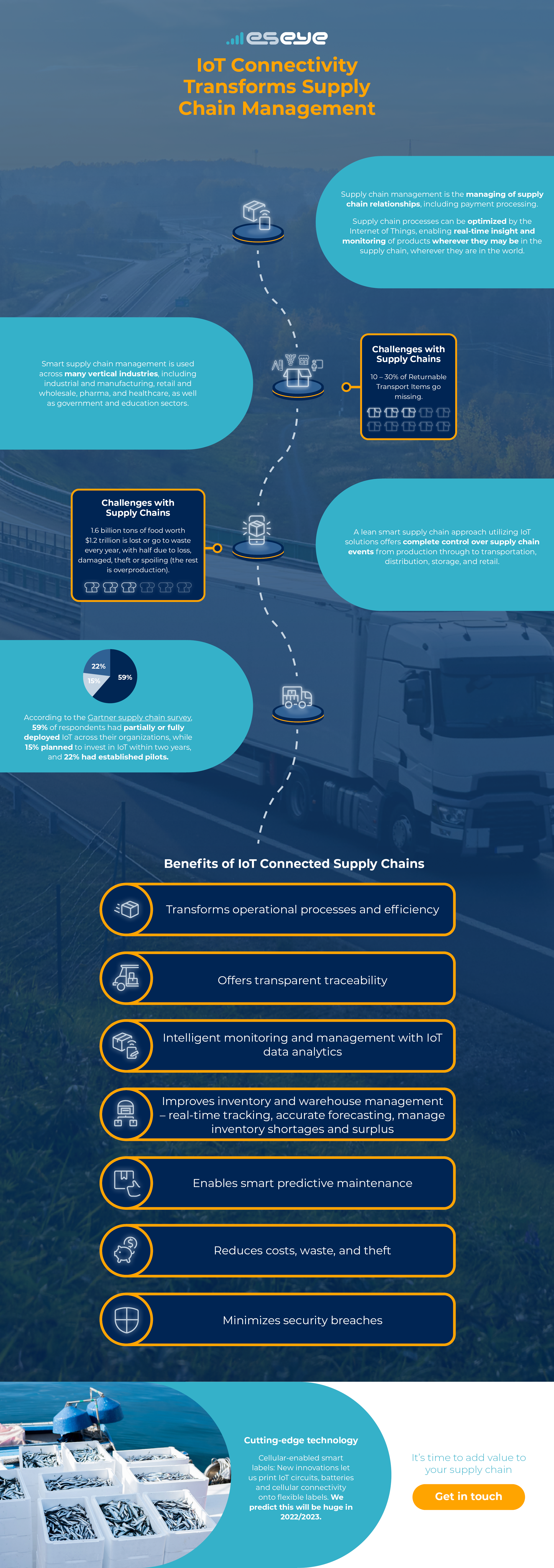

The reality is, that a lot of goods disappear. In fact, various surveys and case studies suggest 10–30% of Returnable Transport Items go missing.

Without real-time data, inbound goods are decoupled from outbound. There is little guarantee against mix-ups and malice.

IoT sensors enable a more granular view of products as they travel through the supply chain. Vehicles and shipping containers are often connected, at least with GPS trackers, so there is oversight of where they are. But the parts within them are usually not. The ‘Returnable Transport Items’ used to carry products – boxes, pallets, kegs, roll cages – move between various vehicles and containers at different legs of the journey. They are ‘checked in’ at various stages, e.g. via a barcode scan or a device that connects to a local network. This gives oversight of where things are at points in time, but not oversight of the whole journey.

This does happen in some very high-value use cases. The new Covid-19 mRNA vaccines, which need very low-temperature storage, are transported in special £5,000 ‘suitcases’ which justify the cost of individual trackers. But this is clearly a different business case from low-value items like tins of tomatoes. But such an approach is becoming feasible for packages of items such as boxes, roll cages, and pallets. It is early days, but viable business cases are starting to emerge, and will only accelerate.

IoT sensors collect real-time data on areas such as location, temperature, tilt, and tamper which can trigger time-critical reactive intervention and optimize proactive monitoring for both perishable and non-perishable goods. This enables supply chain managers to guarantee the safety and quality of the product by maintaining optimum environmental conditions.

Having access to dynamic, real-time data enhances traceability, which is equally important for the product owner and the end consumer.

Knowing where the product has been on its journey and its exact environmental conditions offers vital insights into its condition and help to answer the question: is it fit for use or consumption?

The role supply chain management plays in customer satisfaction through the delivery of products and services is often underestimated. The Chartered Institute of Procurement and Supply (CIPS) states that ‘good supply chain management is critical at reducing operating costs from Procurement activities, through operations and logistics functions and throughout the whole supply chain’. Today, customers are empowered to track their products, whether it’s monitoring a parcel’s route to a destination or tracing a food item back to its source. IoT supply chains make traceability simple and transparent.

Another benefit of continuous real-time monitoring is that security is greatly increased. Events are accurately logged which reduces the risks associated with undetected breaches and loss of inventory en route, such as pallets or roll cages.

Ultimately, transforming operational efficiencies is one – if not, the biggest – benefit that smart supply chains offer.

High-quality IoT data arms supply chain managers with the knowledge and confidence to act upon analytics.

Past statistics can be used to analyse operations and identify specific areas that require improvement. For example, by closely keeping track of assets, managers can improve inventory and warehouse management. Real-time tracking ensures shortages and surpluses can be easily managed and demands can be met.

What’s more, predictive maintenance can truly come into play thanks to IoT sensors. Ultra-fresh data signals if adjustments need to be made – for instance, if demand increases and production needs to ramp up to meet requirements, or if a part in a machine needs replacing before it breaks, so that the production line is not interrupted for a long period. Predictive maintenance helps to fix issues before they become major problems and improves long-term cost-effectiveness.

According to the Gartner supply chain survey, 59% of respondents had partially or fully deployed IoT across their organizations, while 15% planned to invest in IoT within two years, and 22% had established pilots.

IoT is increasingly playing a leading role in supply chain monitoring – offering complete control over supply chain events from production through to transportation, distribution, storage, and retail.

Many vertical industries stand to benefit from connected IoT supply chains, including industrial and manufacturing, retail and wholesale, pharma, and healthcare, as well as government and education sectors.

Here’s an infographic you can use to explore the advantages of IoT-connected supply chains.

Build the IoT estate that meets your needs now – and ten years from now. It’s why global leaders trust Eseye.