Connecting the Fleet:

The role of IoT connectivity in fleet management and telematics

Streamlining fleet operations with IoT

IoT (Internet of Things) technology is increasingly used for fleet and vehicle tracking, monitoring and management, in order to improve efficiency, safety, and the customer experience.

As the industry analyst firm Berg Insight defines it, an IoT fleet management solution is a vehicle-based system that incorporates data logging, satellite positioning and data communications to a back-office application.

Many telematic companies provide conventional CAN bus (Controller Area Network) with their vehicle tracking solutions which monitors diagnostic information such as oil temperature and pressure, mileage, engine hours, excessive braking and so forth.

Typically, a more advanced vehicle telematics solution will include multiple sensors that collect real-time data to provide insights into fleet health, safety, location, maintenance status, in-cab comfort, charging status, and driving behaviour. This information is consolidated by IoT-enabled smart devices, some built into the vehicle, others mounted on the exterior for example the grille or roof. The devices transmit the data via cellular connection to a central IoT platform, which uses software to process it, and uploads it to the cloud for analysis and storage.

Vast amounts of data can be gathered and used by the fleet manager, operator or owner to make quick and accurate decisions, as well as identify trends that will inform longer-term strategy and planning.

Berg Insight predicts that the installed base of fleet management systems will reach 25 million units globally by 2026 – a compound annual growth rate of 13.6% from 13.2 million units at the end of 2021.

Optimizing the fleet with IoT

By developing and deploying an IoT-based fleet management system, manufacturers can offer greater value to their customers, with benefits that enable them to decrease costs, boost efficiency, and reduce accidents and theft. Insights can be drawn from the data to inform smarter, better decision making.

Vehicle tracking

Tracking gives fleet managers precise visibility of where each vehicle is, and when it will be arriving at its destination or returning to the depot. Real-time information brings greater flexibility, with the ability to reallocate vehicles as appropriate or adapt routes to changes in road conditions or the weather. The data gathered can also be applied to accurately predict future requirements, allowing routes to be optimized to minimize fuel consumption and idle time, for example.

Tracking gives fleet managers precise visibility of where each vehicle is, and when it will be arriving at its destination or returning to the depot. Real-time information brings greater flexibility, with the ability to reallocate vehicles as appropriate or adapt routes to changes in road conditions or the weather. The data gathered can also be applied to accurately predict future requirements, allowing routes to be optimized to minimize fuel consumption and idle time, for example.

Improved vehicle performance

Rapid data analytics allows issues or problems that could affect vehicle performance to be identified and proactively addressed. Fleet managers can also use the insights derived on driver behaviour and vehicle usage to determine ways to enhance efficiency. In addition to managing fuel usage, the consistent monitoring of fuel consumption supports sustainability efforts.

Greater driver safety

Real-time statistics on usage and behaviour can enable the fleet manager to intervene to prevent accidents and correct potentially dangerous driving. This is likely to have a positive impact on insurance claims. The data gathered could also be used to support and prove compliance with safety regulations.

Predictive maintenance

An IoT fleet management system can help reduce costs related to downtime, by tracking mileage and hours driven and alerting the fleet operator when a service is due or a repair is necessary. Detailed usage data can help with planning, for example scheduling routine maintenance, or estimating when a vehicle will need to be retired and replaced. Remote diagnostics is also possible, enabling malfunctions to be addressed and parts replaced before the issue gets worse and more expensive to fix.

Asset security

Cameras transmitting real-time video feeds can be used inside and around the vehicle when it’s in transit to monitor cargo conditions, prevent damage or losses, and protect against theft and vandalism.

t42

T42 specialises in wireless systems that track, monitor and protect a variety of assets. Its Helios GPS solution provides automated real-time information on vehicles and drivers, via IoT-enabled devices. T42 required reliable and comprehensive cellular coverage to expand its footprint and support customers globally.

Integrating Eseye’s multi-IMSI AnyNet+ eSIM into its Helios system has brought T42 and its customers consistent and fast global IoT connectivity. Wherever the asset is, T42’s devices instantly connect to the best and most available network, and switch seamlessly to another if connectivity is interrupted, guaranteeing uptime of almost 100 percent. In addition to tracking and securing vehicles, this enables T42 to offer advanced features such as battery status and safety warnings.

If you lose connectivity at that point, you have effectively only achieved 30% availability over the 10 years you expected."

The device design challenge

In a survey undertaken by Kaleido Intelligence and sponsored by Eseye, 84% of respondents cited hardware design as the number one perceived barrier to deploying IoT.

Designing and engineering an IoT device right first time can be problematic. Missing the mark could mean having to redesign the device or even rethink the strategy, resulting in delayed time to value.

Getting the device right involves successfully navigating a number of factors that ensure it will not have a negative impact on vehicle operations or the driver experience. It also needs to be capable of delivering high performance wherever the vehicle is. These factors include creating a seamless user experience, optimizing the sensor and device hardware, and achieving the necessary connectivity and automotive industry certifications.

It’s vital that device performance remains unimpaired as the technology landscape evolves. This means that functionality changes, software and SIM updates will need to be made throughout their lifecycle. Manually updating each device in the field is costly, and will result in delays.

BT Final Mile

BT Final Mile is a smart locker service, introduced by BT with the goal of ensuring that telecoms engineers are no more than 15 minutes’ drive from the parts they need. Its network of intelligent lockers is connected by IoT technology.

Eseye’s in-house IoT device design consultancy brought BT’s vision from idea to proof of concept in weeks, overcoming challenges such as the need for the units to be exceptionally robust. Eseye’s AnyNet+ SIM card is embedded into each locker, delivering 100 percent cellular connectivity by ensuring it’s connected to the strongest possible network at all times. Engineers are instantly alerted when items arrive at the box, and receive one-time codes to unlock them. The devices also track usage and system functionality, and allow firmware updates to be made over-the-air.

As a result of the initiative engineers spend less time travelling, which has enabled BT to reduce its delivery costs and carbon footprint, as well as provide a better service.

This could be because the antenna hasn’t been well designed, or the housing hasn’t been properly considered. Putting in the work early on to optimize the design will avoid any unpleasant surprises.

At Eseye, we reduce the chance of failure by essentially simulating extremely challenging network environments using a private LTE test network that allows customers to check and measure how well their device will perform in situ. Ultimately, we try and break the device connectivity to see how well it recovers or not. Transmission power can be modified depending on the use case: for example, products must continue to provide exceptional performance, even on the fringes of cells. We reduce the power to replicate that scenario. If a customer needs to make revisions to their design, they can complete the work and then retest the device to evaluate whether the required improvement has been made.

AI technology is used to predict and rectify connectivity issues, while real-time data feeds configure alerts…”

Global IoT brings with it a number of connectivity quirks, not least that networks in different countries work on different frequency bands. Again, depending on how the hardware has been designed, you may discover that the device works better on lower frequency bands and not quite so well higher up, for example. Using a private test network also allows customers with international deployments to check their device will work equally as well across all frequency bands.

Taking advantage of a Device Validation service will allow you to build an even more robust design through observing how the device behaves in different connectivity environments, including the worst possible scenarios you could face. How will you pick up on any unusual behaviors and make sure your device is stable? If the networks have different configurations or use modems in different ways, how well will your device work?

...depending on how the hardware has been designed, you may discover that the device works better on lower frequency bands.

Achieving consistently reliable, fast connectivity

In a survey undertaken by Kaleido Intelligence and sponsored by Eseye, 84% of respondents cited hardware design as the number one perceived barrier to deploying IoT.

Designing and engineering an IoT device right first time can be problematic. Missing the mark could mean having to redesign the device or even rethink the strategy, resulting in delayed time to value.

Getting the device right involves successfully navigating a number of factors that ensure it will not have a negative impact on vehicle operations or the driver experience. It also needs to be capable of delivering high performance wherever the vehicle is. These factors include creating a seamless user experience, optimizing the sensor and device hardware, and achieving the necessary connectivity and automotive industry certifications.

It’s vital that device performance remains unimpaired as the technology landscape evolves. This means that functionality changes, software and SIM updates will need to be made throughout their lifecycle. Manually updating each device in the field is costly, and will result in delays.

Rethink uptime

Businesses often think on a per-month basis, focusing on the monthly statistics to gauge how well things are working across their IoT estate. This is of course a crucial metric – but you also need to take the long-term view, looking at how the device will perform over its lifetime. If a device is going out into the field for 10 years, there’s a lot that could change in that period. The mobile network operator (MNO) landscape and legislative environment are constantly evolving, for example.

Three years into the lifecycle of the product, the connectivity it started with may be no longer viable; perhaps due to a roaming agreement that has become uneconomic or been blocked altogether. If you lose connectivity at that point, you have effectively only achieved 30% availability over the 10 years you expected, which will have devastating consequences for the project.

Testing matters

Thinking about geography at a micro level, you need to consider likely variations in connectivity environments. If you’re designing and building your device in a laboratory in a research park where the cellular coverage is extremely good, and then testing it on the lab or office network, it will appear to perform perfectly adequately. However, when it’s taken out into the field, it may work well only when close to the mast and within a much smaller radius than expected.

This could be because the antenna hasn’t been well designed, or the housing hasn’t been properly considered. Putting in the work early on to optimize the design will avoid any unpleasant surprises.

At Eseye, we reduce the chance of failure by essentially simulating extremely challenging network environments using a private LTE test network that allows customers to check and measure how well their device will perform in situ. Ultimately, we try and break the device connectivity to see how well it recovers or not. Transmission power can be modified depending on the use case: for example, products must continue to provide exceptional performance, even on the fringes of cells. We reduce the power to replicate that scenario. If a customer needs to make revisions to their design, they can complete the work and then retest the device to evaluate whether the required improvement has been made.

The use of a multi-IMSI eSIM willgive you the ability to optimize connectivity globally…”

Why work with Eseye on your

IoT project?

Bringing IoT cellular connectivity to fleets of vehicles and other assets has huge advantages for manufacturers and their customers. The ability to generate real-time updates on mission critical data points allows manufacturers to offer competitive and potentially lucrative value-add services. Fleet managers and operators gain a detailed, accurate understanding of vehicle usage, performance, status and condition, which can be leveraged to reduce costs, streamline operations, and improve safety.

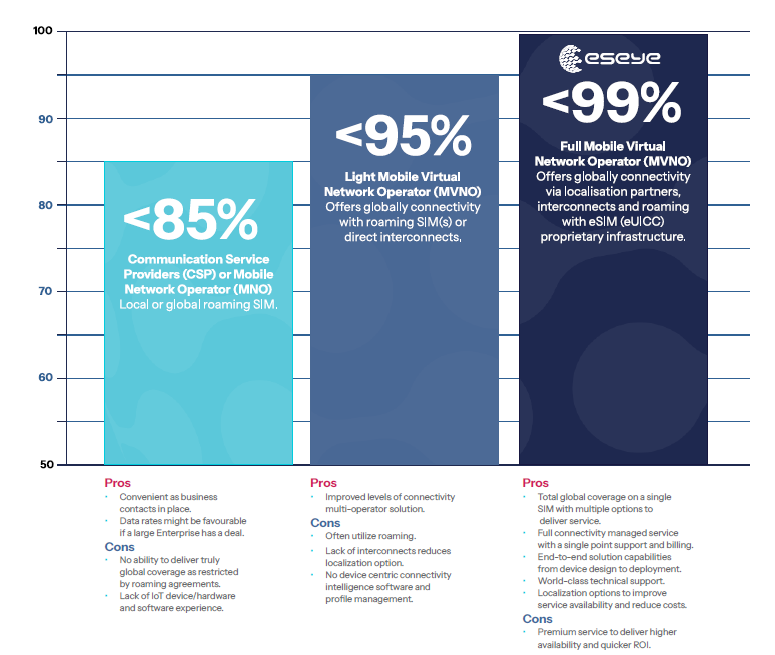

For the potential of an IoT fleet management system to be fully realized, consistent availability and reliability of cellular coverage must be guaranteed, wherever in the world the asset is. This makes choosing the right IoT connectivity solution the most important strategic decision a manufacturer will make.

VDS Technology

VDS Technology has exploited IoT technology to develop a cost-effective intelligent race tracking solution specifically designed for international rallying events. The solution enables organizers to deliver real time race statistics to fans, while playing an important role in safety and security. With global expansion in mind, it needed a SIM card that could be easily deployed in multiple locations.

Eseye’s AnyNet+ eSIM is embedded into each race tracking device, providing seamless access to ubiquitous cellular connectivity on a global scale. This makes it easy to geolocate and monitor competitors across physical borders and even into remote areas. Devices connect straight out-of-the-box – simplifying the logistics of deployment and enabling VDS Technology to offer a ‘turnkey’ solution.

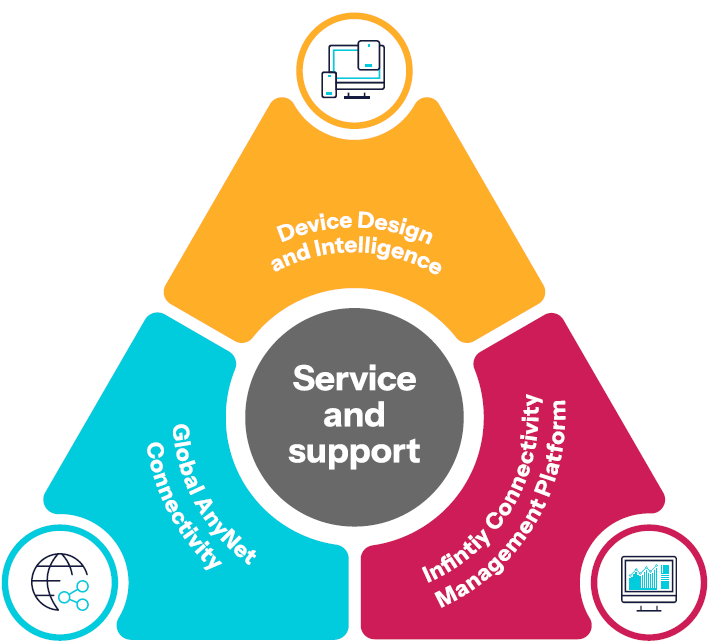

Eseye is a cellular connectivity specialist with a wealth of experience in guiding organizations through complexity to deliver IoT projects successfully. We take a device-first approach to IoT. Working together from the planning and development stage right through to device testing and rollout, we maximise business value while minimising risk.

At the core of our offering is an end-to-end connectivity solution that simplifies and accelerates IoT deployments by enabling customers to work with one partner, one SIM card, one platform, and one bill.

Our award-winning AnyNet+ eSIM allows stable and ubiquitous cellular connectivity to be built into fleet management devices by design. Using eUICC technology, the eSIM can store multiple network profiles and these can be automatically provisioned and managed over-the-air. In practice this means your tracking devices connect to the most available mobile network, wherever the asset is, thanks to Eseye’s relationships with more than 800 operators in 190 countries. Each SIM can be loaded with multiple network profiles (multi-IMSI), allowing each device to be localized, which brings cost efficiencies and improves operations.

Updates to the unit’s software, firmware and connectivity can be made instantly and at scale, over-the-air, helping to future-proof the system so it lasts for the vehicle’s lifetime. A single global product SKU for the eSIM streamlines the supply chain and manufacturing processes, supports global expansion, and makes billing easier.

Our team of technical consultants is absolutely intent on taking proactive action to get connectivity working as well as it possibly can.”

What you don’t know can hurt you.

Unbeaten IoT connectivity expertise, service, and support

Every single percentage of service uptime matters. That’s why choosing a cellular connectivity provider on cost, or opting for a SIM card supplier who simply resells connectivity, is unlikely to get you to where you want to be.

Your connectivity partner should be immersed in IoT design, development, and operation day in and day out. They must understand what you are trying to do and be ready to help you achieve the maximum uptime possible so that your business case is successful.

Eseye has the required deep IoT expertise and experience, codified within our industry-leading technology tools, which is why Kaleido Intelligence Vendor Hub has named us the no.1 market leader in eSIM Connectivity Solutions for four consecutive years.

Our team of technical consultants is absolutely intent on taking proactive action to get connectivity working as well as it possibly can. If something isn’t right, we work with you to investigate the catalyst for the problem and to close the gap.

Eseye is equipped with the capabilities to guarantee unbeaten IoT cellular connectivity coverage globally, at every stage of your IoT project.

Our team of technical consultants is absolutely intent on taking proactive action to get connectivity working as well as it possibly can.

The device design challenge

The device design challenge

In a survey undertaken by Kaleido Intelligence and sponsored by Eseye, 84% of respondents cited hardware design as the number one perceived barrier to deploying IoT.

Designing and engineering an IoT device right first time can be problematic. Missing the mark could mean having to redesign the device or even rethink the strategy, resulting in delayed time to value.

Getting the device right involves successfully navigating a number of factors that ensure it will not have a negative impact on vehicle operations or the driver experience. It also needs to be capable of delivering high performance wherever the vehicle is. These factors include creating a seamless user experience, optimizing the sensor and device hardware, and achieving the necessary connectivity and automotive industry certifications.

It’s vital that device performance remains unimpaired as the technology landscape evolves. This means that functionality changes, software and SIM updates will need to be made throughout their lifecycle. Manually updating each device in the field is costly, and will result in delays.

Rethink uptime

Businesses often think on a per-month basis, focusing on the monthly statistics to gauge how well things are working across their IoT estate. This is of course a crucial metric – but you also need to take the long-term view, looking at how the device will perform over its lifetime. If a device is going out into the field for 10 years, there’s a lot that could change in that period. The mobile network operator (MNO) landscape and legislative environment are constantly evolving, for example.

Three years into the lifecycle of the product, the connectivity it started with may be no longer viable; perhaps due to a roaming agreement that has become uneconomic or been blocked altogether. If you lose connectivity at that point, you have effectively only achieved 30% availability over the 10 years you expected, which will have devastating consequences for the project.

Testing matters

Thinking about geography at a micro level, you need to consider likely variations in connectivity environments. If you’re designing and building your device in a laboratory in a research park where the cellular coverage is extremely good, and then testing it on the lab or office network, it will appear to perform perfectly adequately. However, when it’s taken out into the field, it may work well only when close to the mast and within a much smaller radius than expected.

This could be because the antenna hasn’t been well designed, or the housing hasn’t been properly considered. Putting in the work early on to optimize the design will avoid any unpleasant surprises.

At Eseye, we reduce the chance of failure by essentially simulating extremely challenging network environments using a private LTE test network that allows customers to check and measure how well their device will perform in situ. Ultimately, we try and break the device connectivity to see how well it recovers or not. Transmission power can be modified depending on the use case: for example, products must continue to provide exceptional performance, even on the fringes of cells. We reduce the power to replicate that scenario. If a customer needs to make revisions to their design, they can complete the work and then retest the device to evaluate whether the required improvement has been made.

Customers’ deployment are futureproofed with the ability to rapidly and remotely add new MNO interconnects”

Customers’ deployment are futureproofed with the ability to rapidly and remotely add new MNO interconnects”

Unbeaten IoT connectivity expertise, service, and support

Every single percentage of service uptime matters. That’s why choosing a cellular connectivity provider on cost, or opting for a SIM card supplier who simply resells connectivity, is unlikely to get you to where you want to be.

Your connectivity partner should be immersed in IoT design, development, and operation day in and day out. They must understand what you are trying to do and be ready to help you achieve the maximum uptime possible so that your business case is successful.

Eseye has the required deep IoT expertise and experience, codified within our industry-leading technology tools, which is why Kaleido Intelligence Vendor Hub has named us the no.1 market leader in eSIM Connectivity Solutions for four consecutive years.

Our team of technical consultants is absolutely intent on taking proactive action to get connectivity working as well as it possibly can. If something isn’t right, we work with you to investigate the catalyst for the problem and to close the gap.

Eseye is equipped with the capabilities to guarantee unbeaten IoT cellular connectivity coverage globally, at every stage of your IoT project.

Our team of technical consultants is absolutely intent on taking proactive action to get connectivity working as well as it possibly can.

The device design challenge

The device design challenge

In a survey undertaken by Kaleido Intelligence and sponsored by Eseye, 84% of respondents cited hardware design as the number one perceived barrier to deploying IoT.

Designing and engineering an IoT device right first time can be problematic. Missing the mark could mean having to redesign the device or even rethink the strategy, resulting in delayed time to value.

Getting the device right involves successfully navigating a number of factors that ensure it will not have a negative impact on vehicle operations or the driver experience. It also needs to be capable of delivering high performance wherever the vehicle is. These factors include creating a seamless user experience, optimizing the sensor and device hardware, and achieving the necessary connectivity and automotive industry certifications.

It’s vital that device performance remains unimpaired as the technology landscape evolves. This means that functionality changes, software and SIM updates will need to be made throughout their lifecycle. Manually updating each device in the field is costly, and will result in delays.

Rethink uptime

Businesses often think on a per-month basis, focusing on the monthly statistics to gauge how well things are working across their IoT estate. This is of course a crucial metric – but you also need to take the long-term view, looking at how the device will perform over its lifetime. If a device is going out into the field for 10 years, there’s a lot that could change in that period. The mobile network operator (MNO) landscape and legislative environment are constantly evolving, for example.

Three years into the lifecycle of the product, the connectivity it started with may be no longer viable; perhaps due to a roaming agreement that has become uneconomic or been blocked altogether. If you lose connectivity at that point, you have effectively only achieved 30% availability over the 10 years you expected, which will have devastating consequences for the project.

Testing matters

Thinking about geography at a micro level, you need to consider likely variations in connectivity environments. If you’re designing and building your device in a laboratory in a research park where the cellular coverage is extremely good, and then testing it on the lab or office network, it will appear to perform perfectly adequately. However, when it’s taken out into the field, it may work well only when close to the mast and within a much smaller radius than expected.

This could be because the antenna hasn’t been well designed, or the housing hasn’t been properly considered. Putting in the work early on to optimize the design will avoid any unpleasant surprises.

At Eseye, we reduce the chance of failure by essentially simulating extremely challenging network environments using a private LTE test network that allows customers to check and measure how well their device will perform in situ. Ultimately, we try and break the device connectivity to see how well it recovers or not. Transmission power can be modified depending on the use case: for example, products must continue to provide exceptional performance, even on the fringes of cells. We reduce the power to replicate that scenario. If a customer needs to make revisions to their design, they can complete the work and then retest the device to evaluate whether the required improvement has been made.

Customers’ deployment are futureproofed with the ability to rapidly and remotely add new MNO interconnects”

Customers’ deployment are futureproofed with the ability to rapidly and remotely add new MNO interconnects”

Unbeaten device design and intelligence

Bespoke consultancy from our specialists across design and prototyping, development, testing and evaluation, onboarding, and certification to ensure your device works anywhere in the world and will continue to do so into the future.

Unbeaten global connectivity and Connectivity Management Platform:

Since working with Eseye, we’ve recorded an 87.5% improvement in connectivity performance compared to our previous cellular provider, and we’re working with Eseye daily to make even greater improvements. In doing this we have reached 99.6% connectivity which is better than we expected, and it continues to get better every day."

Fred Roe, Vice President of Sales, PharmaWatch