IoT Explained

30 June 2021

Reading Time: 3 mins

IoT Explained

30 June 2021

Reading Time: 3 mins

Paul Marshall

Founder & CCO

LinkedInIn our article Why Your End of Line Testing of IoT Devices Might Be Failing Without You Knowing, we described the potential pitfalls of using a live local network to test your devices in the production environment. Devices can pass even if they have faults, for example, if the cellular signal is artificially boosted. In other cases, they can be failed unfairly if the factory receives an unreliable cellular signal. Sometimes planned connectivity testing doesn’t work at all in the manufacturing facility.

In this article, we outline our recommendations for creating a controlled, repeatable process for end of line testing of IoT devices in a production facility.

Efficient and reliable end of line testing of IoT device connectivity needs a process and environment that together enable controlled, repeatable, and comprehensive testing.

There are two ways this can be done.

Communications modules have a test mode that’s designed for testing devices in a factory setting.

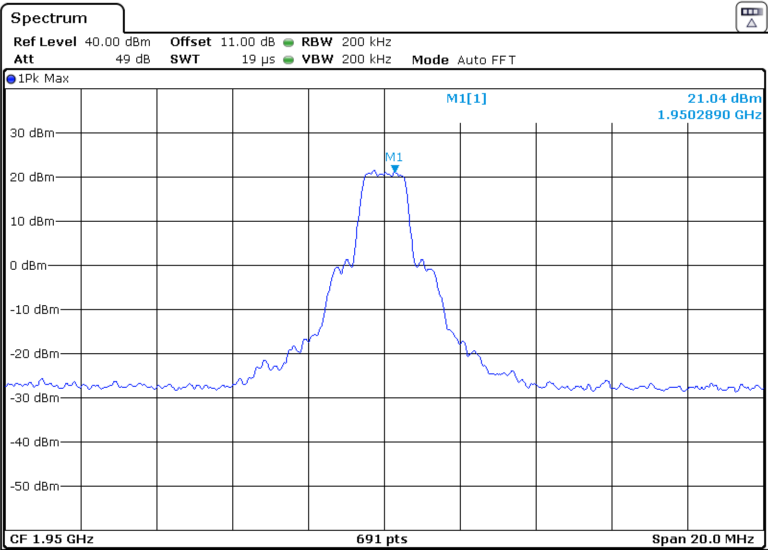

Different modules have different test capabilities, but in general they enable a device to transmit test signals on command using an unmodulated carrier. Test equipment, such as a spectrum analyser, can be configured to receive this signal and check characteristics, such as its amplitude, frequency, and power.

The tests can be designed to cover all connectivity requirements, such as the frequencies, channels, bands, and signal strength, that the device needs to handle. They can also ensure that the modem can communicate with the SIM and read information such as the SIM number.

How a device receives signals can be tested by using the receive test mode and an RF signal generator to produce a defined, unmodulated output signal. Test measurements can show how the module is performing input filtering.

Modem manufacturers can supply application notes to guide users through the methods of thoroughly testing both transmit and receive functions on all the frequency bands that their modem can use.

A small cell is a low-powered cellular radio system with a range of 10 meters to a few kilometres. Setting up a small network within a production plant gives you full control of how you test your devices. Tests are reliable, repeatable, and can cover all your device connectivity requirements.

Key features and requirements:

Connecting to a local network to test connectivity during the end of line testing process presents an increasing number of challenges. We recommend that customers explore the options that provide better ways to perform this testing with improved test coverage and reduced test time, cost, and risk.

A test process that uses the module’s test mode and equipment such as a spectrum analyser is the most straightforward option. It minimises costs as most plants already have this type of equipment and the skills to configure and use it.

Setting up your own small cell network in the production plant is a more complex and costly option. Your connectivity provider needs to supply SIMs that are provisioned with a test profile and the ability to change to a live profile when testing is complete. You need to know how to configure your small cell and test process to cover the testing that’s required. However, this method provides the most realistic environment in which to test your devices and gives the most control over the coverage, reliability, and repeatability of your testing process.

At Eseye, we have extensive experience of setting up IoT deployments and understand the problems that can arise with end of line testing of IoT devices. We also see – and help solve – problems that arise in the field because connectivity issues weren’t identified during end of line testing.

Paul Marshall

Founder & CCO

LinkedInPaul is one of Eseye’s co-founders. With a background in senior design engineering, Paul’s focus is on ensuring his development, operations and support teams deliver solutions that work faultlessly in the field.

Paul was co-founder of CompXs, with Ian Marsden, and developed the world’s first IEEE 802.15.4 radio. Before CompXs, Paul was in senior radio design at Philips.

Learn how our IoT device design and connectivity expertise can accelerate your project from conception to deployment.

Learn more