Smart Farming IoT Success

Connected Cow IoT Solution Enables Early Disease Diagnosis.

Learn why Precision Animal Solutions chose Eseye for its device-first approach and help creating a custom hardware solution and successful proof of concept for the REDI (Remote Early Disease Identification) system.

About Precision Animal Solutions

Founded by two veterinarians Brad White and Dan Goehl with a combined 35 years in the animal health business, Precision Animal Solutions is a leading provider of animal behaviour monitoring set to revolutionise farming and agriculture using continuous monitoring IoT solutions.

The number one challenge cattle face

Millions of cattle die from bovine respiratory disease (BRD) each year. Early and accurate diagnosis is critical – but previously this could only be done through human observation. This was extremely time-consuming, and many cases were not picked up until too late, costing the US beef industry an estimated $1 billion per year.

When cows are ill, their behaviour changes drastically: they’re less social, and they don’t eat and drink as frequently. Precision Animal Solutions’ REDI (Remote Early Disease Identification) system monitors the location and behaviour of cattle in real-time, using sensors attached to the animals. These detect and report how often cows come near one another, the feeding area, and the water area. When concerning behaviour is spotted a light on the sensor identifies the cow so it can be quickly quarantined, treated, and saved.

In 2021, Precision Animal Solutions approached Eseye to help it develop a proof of concept of an IoT hardware solution for its REDI system that could be scaled to large commercial deployments. The choice of partner was based on Eseye’s unique blend of hardware and solution architecture expertise, combined with its multi-carrier and resilient IoT connectivity capabilities.

We approached the BRD challenge backwards by starting with the problem. How could we best monitor animals to determine whether they’re sick or not? We needed to measure behaviour, and then we identified what we needed to collect.

Brad White, Veterinarian, Professor, and Partner, Precision Animal Solutions

Why Precision Animal Solutions chose Eseye

Custom Device-First Approach

Eseye’s IoT Device Design Services team helped create a custom hardware solution and developed a successful proof of concept for its REDI (Remote Early Disease Identification) system.

Greater Diagnostic Accuracy

The REDI solution correctly identifies BRD in 81% of cases, compared to 64% with visual observers. Automatic tracking has improved efficiency and lowered manual effort.

Out-of-the-Box Connectivity

Each tracker is ready to go meaning Precision Animal Solutions can achieve extremely high levels of connectivity reach and uptime anywhere in the world.

Brad White, Partner, explains the unique consultative approach Eseye took

Precision Animal Solutions developed its wireless-enabled REDI solution, which automates the discovery of BRD for cattle producers, improving animal welfare and reducing losses. The project presented a number of operational challenges, along with unique hardware, software, and physical packaging requirements.

The REDI solution would need to be safe for animals, have a small footprint, and require little infrastructure or maintenance. It was also important that the hardware system used to collect the data was robust, and wouldn’t require farmers and beef producers to disrupt their normal processes.

Eseye has brought the company the device design expertise and reliable connectivity it needs to turn the REDI concept into reality.

Smart Farming Success

What our

customers say

Want the full story?

Take a deeper dive into Precision Animal's IoT journey. Find out how we helped them overcome hurdles and challenges that might stall your IoT project, and see how we can help your business succeed with IoT.

Harnessing IoT with Precision Animal Solutions

IoT hardware and connectivity expertise

Precision Animal Solutions took full advantage of Eseye’s IoT Device Design Services to reduce risk, avoid development challenges, and lower the cost of solution development.

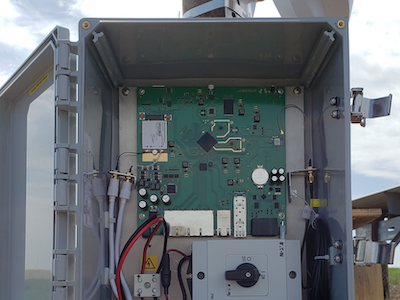

Eseye’s team of engineers designed, built and evaluated a proof-of-concept solution that consisted of two physical components: a customised bovine tracker, and the REDI gateway.

Eseye miniaturised the initial IoT prototype to a small and light enough tracker – weighing less than 30g – that can be easily attached to each cow. This involved the development of a bespoke circuit board. The trackers are reusable to reduce waste.

From cow to cloud

The REDI trackers form a network of sensors that connect to each other, as well as to a gateway that is positioned in or around the containment pen. The tracker collects data on an animal’s behaviour, stores it in the memory of the sensor, and uploads it to the gateway via Bluetooth when a cow comes near it.

The REDI gateway reads the data from the tracker and uploads it to an AWS cloud platform where Precision Animal Solutions processes and analyses it using its proprietary algorithms to identify differences in behaviour.

To meet the client’s goals for sustainability and ease of installation, the gateway is powered by a solar panel with a long-life, easily replaceable battery. And each tracker is fully reusable and built for long-term use.

Track and trace response

If a cow becomes unwell with BRD, it needs to be removed from the herd quickly to avoid other cattle becoming infected and allow fast treatment with antimicrobials to halt the progression of the disease. There is simply no room for connectivity failures.

Eseye used its hardware and design expertise to create a custom solution to connect the trackers, and enable reliable communication with the REDI gateway.

The platform was specially customised to support Bluetooth technology as well as cellular functions. Encased in rugged aluminium, it also supports the need for the gateway to withstand the elements in an outdoor environment.

Custom hardware

The custom hardware solution works hand in hand with Eseye’s managed connectivity service to ensure high device uptime. Underpinned by the Infinity IoT Connectivity Management Platform, this service enables resilient global connectivity for the REDI system, ensuring devices remain connected to the best possible cellular network at any time. Eseye also assisted with securing the necessary FCC, Bluetooth and cellular certification for the REDI system.

Following the launch and deployment of the solution, Eseye will provide Device Lifecycle Management Services and Design Consultancy Services on an ongoing basis. This will involve making any component changes and application modifications needed as production requirements change and technology evolves.

Resources

Rise of the eSIM orchestrator Webinar With Transforma Insights

IoT and the Future of Digital Out-of-Home (DOOH) Advertising

IoT and Agentic AI Power Tomorrow’s Smart Hospitals

Three Quarters of Enterprises Hit by IoT Attacks as Device Security Becomes ‘Weakest Link’

Award-winning IoT Start your journey today.

Find out how we can support your Smart Vending project